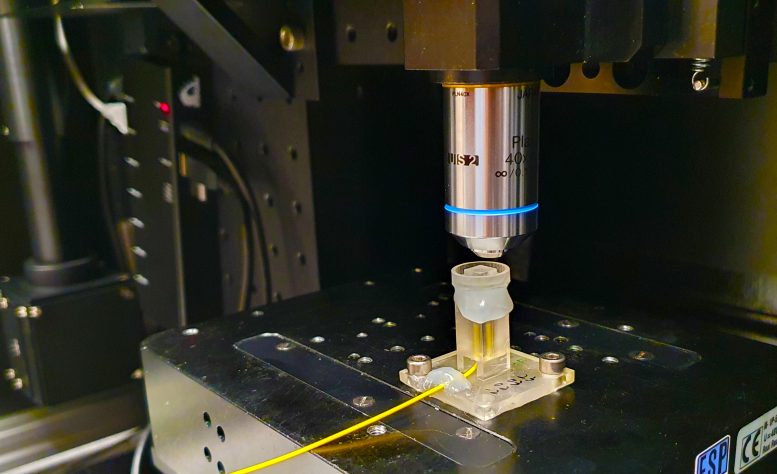

Swedish researchers have innovated 3D printing by creating silica glass micro-optics on optical fibers, promising sooner web, improved sensors, and superior imaging methods, whereas avoiding high-temperature harm to fiber coatings. Credit score: David Callahan

Swedish researchers have 3D-printed silica glass micro-optics on optical fibers, enhancing web velocity and connectivity. This system, extra resilient and exact, may revolutionize distant sensing, prescribed drugs, and photonics.

In a primary for communications, Swedish researchers have efficiently 3D printed silica glass micro-optics straight onto the ideas of optical fibers, areas as tiny because the cross-section of a human hair. This breakthrough may result in sooner web speeds and enhanced connectivity, together with the event of smaller sensors and extra compact imaging methods.

Reporting within the journal ACS Nano, researchers at KTH Royal Institute of Know-how in Stockholm say integrating silica glass optical units with optical fibers allows a number of improvements, together with extra delicate distant sensors for the surroundings and healthcare.

The printing strategies they report additionally may show priceless within the manufacturing of prescribed drugs and chemical compounds.

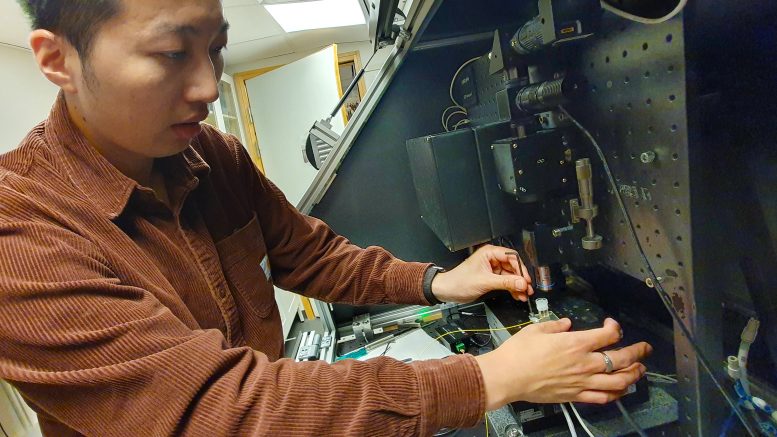

Lee-Lun Lai demonstrates the setup to print silica glass microstructures on an optical fiber. Credit score: Lee-Lun Lai demonstrates the setup to print silica glass microstructures on an optical fiber.

Developments in Printing Strategies

KTH Professor Kristinn Gylfason says the tactic overcomes longstanding limitations in structuring optical fiber suggestions with silica glass, which he says typically require high-temperature remedies that compromise the integrity of temperature-sensitive fiber coatings. In distinction to different strategies, the method begins with a base materials that doesn’t comprise carbon. Which means excessive temperatures usually are not wanted to drive out carbon with a purpose to make the glass construction clear.

The examine’s lead creator, Lee-Lun Lai, says the researchers printed a silica glass sensor that proved extra resilient than a typical plastic-based sensor after a number of measurements.

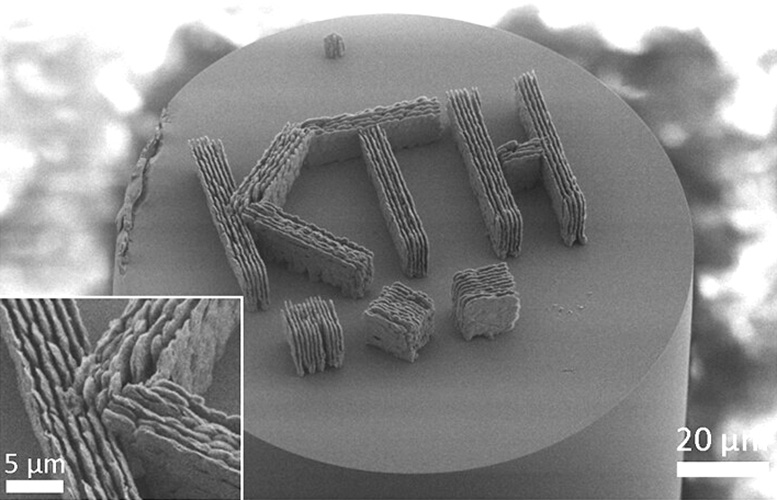

Microscopic picture of a printed glass demonstration construction on tip of optical fiber. Credit score: David Callahan

“We demonstrated a glass refractive index sensor built-in into the fiber tip that allowed us to measure the focus of natural solvents. This measurement is difficult for polymer-based sensors as a result of corrosiveness of the solvents,” Lai says.

“These constructions are so small you could possibly match 1,000 of them on the floor of a grain of sand, which is concerning the measurement of sensors getting used at present,” says the examine’s co-author, Po-Han Huang.

The researchers additionally demonstrated a way for printing nanogratings, ultra-small patterns etched onto surfaces on the nanometer scale. These are used to control gentle in exact methods and have potential purposes in quantum communication.

Gylfason says the flexibility to 3D print arbitrary glass constructions straight on fiber tip opens new frontiers in photonics. “By bridging the hole between 3D printing and photonics, the implications of this analysis are far-reaching, with potential purposes in microfluidic units, MEMS accelerometers, and fiber-integrated quantum emitters,” he says.

Reference: “3D Printing of Glass Micro-Optics with Subwavelength Options on Optical Fiber Suggestions” by Lee-Lun Lai, Po-Han Huang, Göran Stemme, Frank Niklaus and Kristinn B. Gylfason, 29 March 2024, ACS Nano.

DOI: 10.1021/acsnano.3c11030

The examine was funded by the Sweden Taiwan Analysis Initiatives 2019 and the Swedish Basis for Strategic Analysis.