Researchers have developed the primary 3D printable ocular resins with the potential to supply better complexity and customisable intraocular lens (IOL) designs.

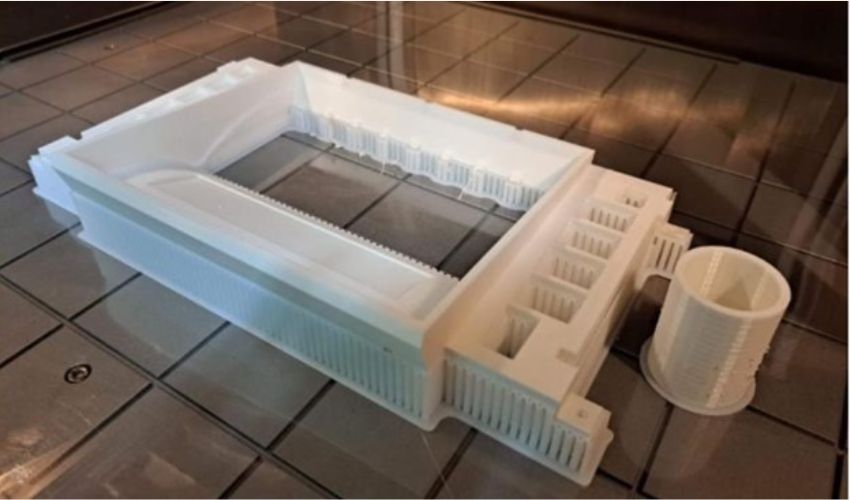

Within the examine, printed in Present Eye Analysis, the researchers created lens-like 3D objects utilizing stereolithography. The lenses have been discovered to have good readability, biocompatibility, and have been foldable when injected right into a human lens capsule.

Hydrophilic and hydrophobic acrylic are the 2 most generally used supplies in IOL manufacturing for his or her optical readability, flexibility, biocompatibility, stability and security within the eye.

IOLs are sometimes made utilizing lathing and moulding methods, which produce high-quality gadgets however restrict design customisation choices.

Along with tailoring lenses to every affected person and creating advanced designs which might be tough to fabricate with conventional strategies, utilizing 3D printing might allow sooner manufacturing of IOLs to scale back the time between analysis and surgical procedure.

Additional, 3D printing might scale back manufacturing prices and enhance affordability to sufferers.

“We’ve proven that IOLs could possibly be quickly prototyped with out the requirement to first develop particular IOL moulds or intensive lathing processes,” the examine authors mentioned.

“Thus, this may facilitate the creation of novel IOL designs that might be very tough to prototype with conventional manufacturing strategies.”

Extra studying

How Alcon’s Vivity is disrupting the Australian IOL panorama

Visible implant developed with ‘electrodes the dimensions of a single neuron’

Analysis edges nearer to another for intravitreal drug supply