Wipro 3D a supplier of 3D printing providers, joins forces with the Indian House Analysis Organisation (ISRO), to fabricate a PS4 3D-printed rocket engine. The rocket engine powers the 4th stage of the Polar Satellite tv for pc Launch Car (PSLV), an expendable launch system designed to put earth commentary and Scientific satellites into exact orbits enabling a number of functions like distant sensing, oceanography, cartography, mineral mapping, catastrophe warning and so on.

To make sure correct orbital placement, the PS4 stage is supplied with superior navigation, steerage and management programs. Its adaptability for various sorts of spacecraft missions is enhanced by its skill to assist a number of restart capabilities and payload adapters.

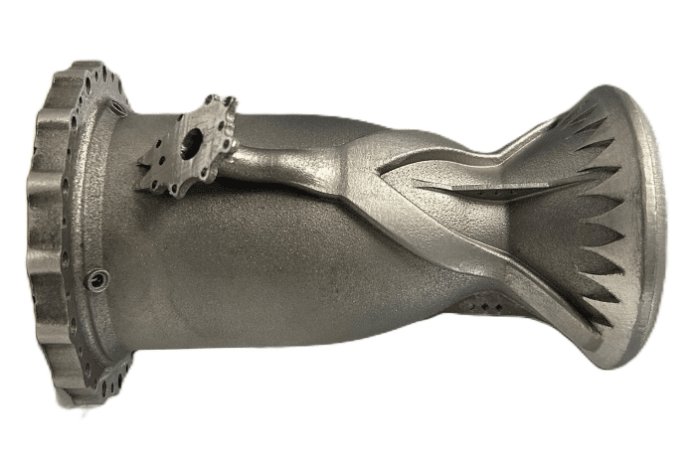

The PS4 engine, historically manufactured by means of standard machining and welding, underwent a redesign because of Additive Manufacturing.

The 2 companions relied on Design for Additive Manufacturing (DfAM) and Laser Powder Mattress Fusion (LPBF) know-how, to consolidate the a number of and diversified PS4 engine intricate parts right into a single unified manufacturing unit, enhancing manufacturing effectivity and structural integrity.

Yathiraj Kasal, GM & Enterprise Head, Wipro 3D, expressed, “We’re honored to collaborate with ISRO on this pioneering undertaking, highlighting the potential of superior manufacturing in House. This partnership not solely advances ISRO’s ‘Make in India’ initiative but in addition promotes home innovation and manufacturing. It’s an honor and a privilege to fabricate the PS4 engine for the PSLV automobile. We’re eagerly awaiting the profitable second spherical of testing to fly excessive alongside ISRO.”

The 3D-printed PS4 engine, that includes integral advanced cooling channels, prioritizes sustainability and effectivity in its design, with minimal materials wastage and post-print machining operations. Rigorous testing of the {hardware} on the services at ISRO Propulsion Advanced in Mahendragiri confirmed the engine’s efficiency beneath real-world circumstances, assembly the design security and effectivity requirements.

The important thing efficiency metrics of the ISRO 3D-Printed Rocket Engine prolonged length check included optimum chamber strain, gas administration, combustion effectivity, and particular impulse (Isp). ISRO’s adoption of additive manufacturing affords superior precision, minimal useful resource utilization, and vital reductions in materials wastage and manufacturing time.

Keep in mind, you may put up job alternatives within the AM Trade on 3D ADEPT Media freed from cost or search for a job by way of our job board. Ensure that to comply with us on our social networks and subscribe to our weekly e-newsletter : Fb, Twitter, LinkedIn & Instagram ! If you wish to be featured within the subsequent concern of our digital journal or when you hear a narrative that must be heard, be certain that to ship it to [email protected]