A brand new kind of 3D-printed adhesive may change how we be part of supplies collectively. To this point, scientists have developed two new strategies that may create extraordinarily sturdy bonds on the pore stage, eliminating the necessity to add extra glues to the bonding course of.

Whereas glues and different industrial-level adhesives are notably sturdy at holding issues collectively, they aren’t nice contenders for the setting. In actual fact, they typically require huge quantities of vitality and assets to provide. And whereas we’ve got tried to create extra eco-friendly choices, these new strategies take issues a lot additional.

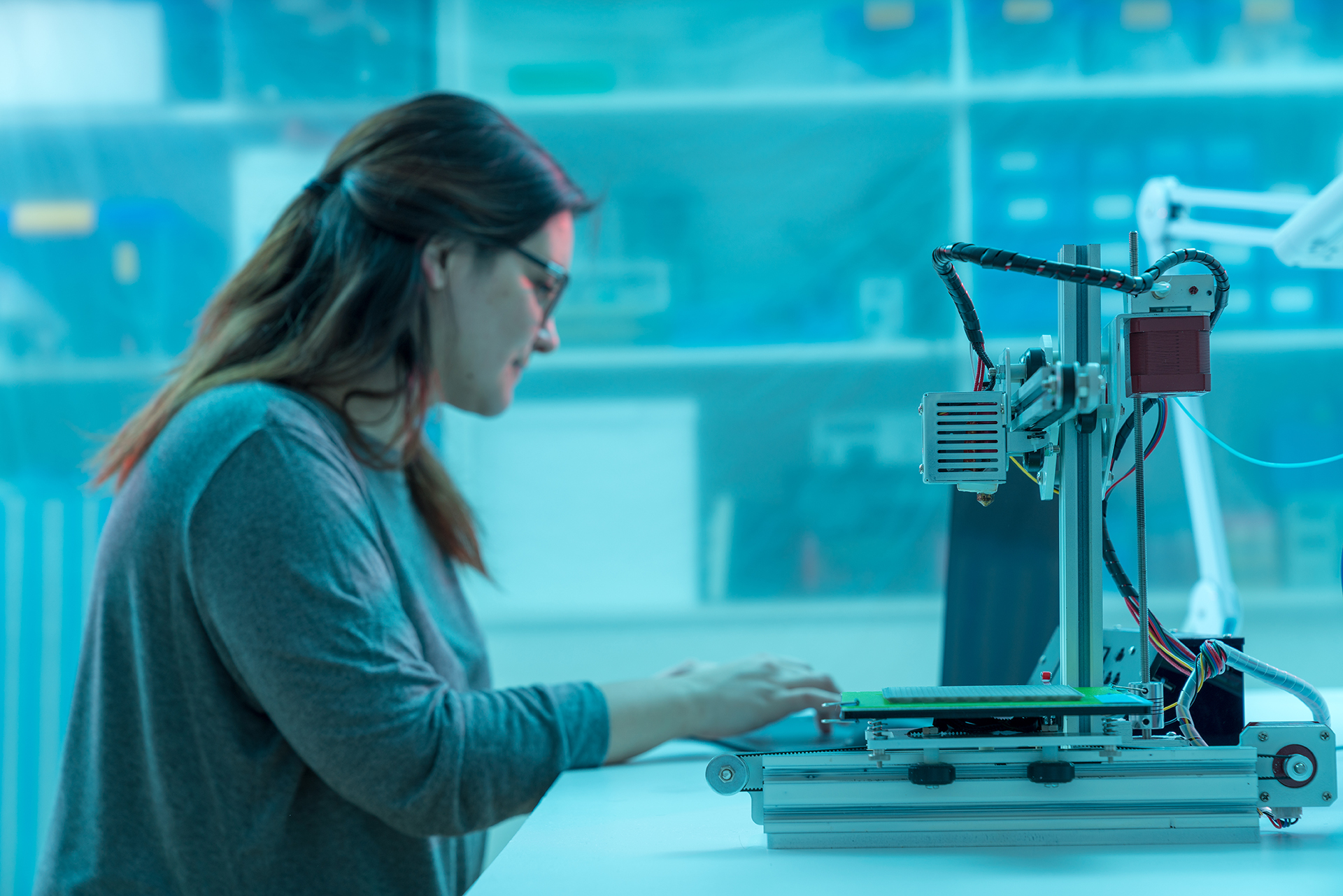

In actual fact, the brand new strategies depend on 3D printing to connect the gadgets collectively on the pore stage, which has led to the method being termed “AddJoining.” Basically, the totally different components of an merchandise are printed instantly onto a chunk of untreated wooden, permitting the fabric to penetrate the pores. This creates a particular kind of 3D-printed adhesive.

When testing the energy of the brand new strategies, the researchers concerned discovered that once they snapped the bond, the adhesive portion itself didn’t break. As a substitute, the fracture occurred within the wooden and the polymer itself, not the joint. Which means that creating 3D-printed bonds may very well be the way forward for how we adhere issues collectively.

Additional, the researchers consider that layering the 3D-printed adhesive on prime of the wooden that has been etched with a laser may assist create way more advanced buildings and bigger pores for the bond to sink into. This time, nevertheless, they needed to maintain issues so simple as potential.

3D printing has confirmed to be actually efficient in a number of fields, together with constructing complete homes. Maybe future assessments will assist us see simply how sturdy the bond may be, particularly if the floor is etched with a laser earlier than printing the part onto it. The researchers showcased their work at July’s seventh IIW Annual Meeting and Worldwide Convention.