When pondering of banking tools, most individuals conjure a picture of old style money-counting machines or instruments utilized by tellers sitting behind their counters. However as one of many oldest professions, courting again to information from round 2000 BCE in historic Mesopotamia, it stands to cause that banking and its establishments are continuously seeking to innovate. As banking trade evolves from its historic roots, establishments like Diebold Nixdorf are on the forefront of innovation, leveraging cutting-edge applied sciences to revolutionize their operations. A notable leap on this journey is the combination of 3D printing into their manufacturing processes, and extra particularly of INTAMSYS 3D printing options.

Diebold Nixdorf is an American multinational firm, chief within the manufacturing of revolutionary banking options and retail expertise. Specifically, the corporate focuses on banking automation, producing ATMs, good safes, and inquiry terminals. Since October 2020, Diebold Nixdorf has partnered with FPFTech (Fundação Amazônica for Assist to Analysis and Technological Growth Decide Paulo dos Anjos), a non-profit Analysis and Growth establishment, to undertake additive manufacturing in its manufacturing processes, with the help of INTAMSYS.

Diebold Nixdorf is thought for its automated banking options (picture credit: Diebold Nixdorf)

Why Did Diebold Nixdorf Flip to 3D Printing?

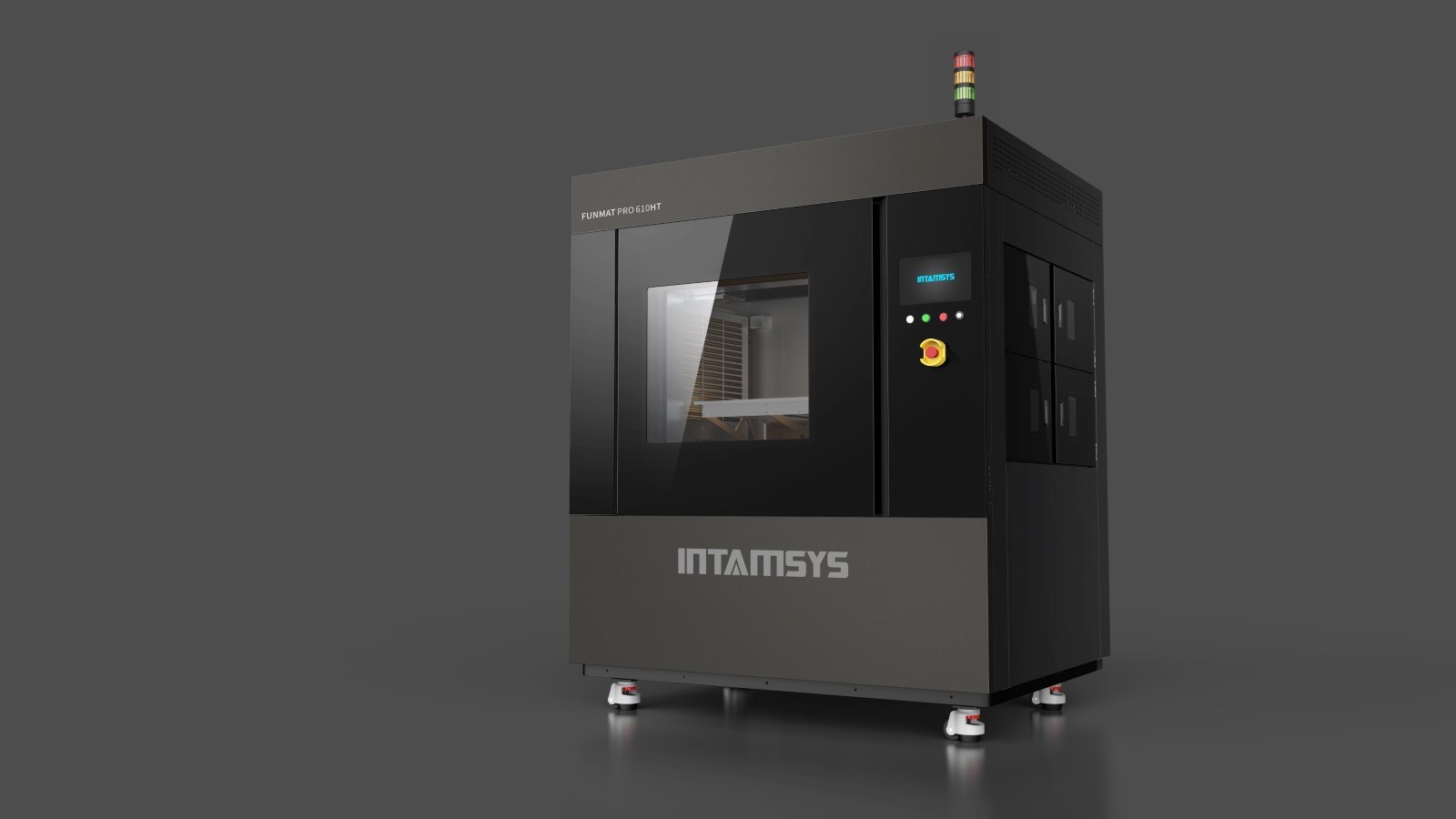

Although banking options is probably not what we most hear about in relation to purposes the place 3D printing is beneficial, within the case of Diebold Nixdorf, it appears to have turn into an integral a part of manufacturing. Diebold Nixdorf selected two 3D printers to fulfill their manufacturing wants. This consists of one from INTAMSYS, the massive construct quantity FFF 3D printer FUNMAT PRO 610HT for big elements and extra materials alternative (notably with high-performance filaments).

However why precisely did Diebold Nixdorf flip to 3D printing? Properly, it’s a story now we have heard again and again, the adoption of additive manufacturing, notably by way of INTAMSYS has enabled the manufacturing of conceptual and practical prototypes with unprecedented precision and high quality. All whereas additionally providing vital value and time financial savings.

Julio Pinheiro, venture supervisor at Diebold Nixdorf additional explains, “The choice to make use of 3D printing got here from the necessity to carry extra agility and adaptability to the event of our merchandise. It permits fast prototyping of complicated parts that beforehand required way more time and assets. Beforehand, we relied closely on machining and constructing bodily fashions, which actually slowed down the event cycle. With 3D printing, not solely have we accelerated this course of, however now we have additionally considerably diminished the related prices.”

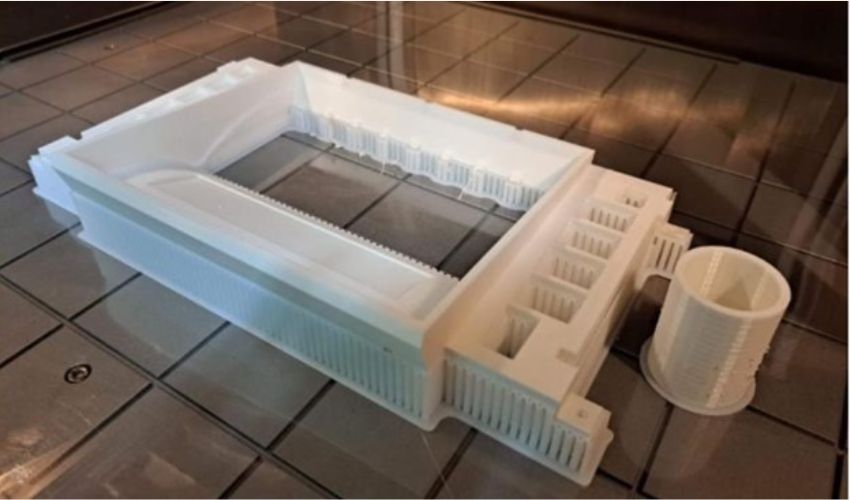

A entrance panel made utilizing the INTAMSYS FUNMAT PRO 610HT with help materials eliminated (picture credit: INTAMSYS)

The Selection of Printer

It was no accident both that the corporate turned particularly to the INTAMSYS FUNMAT PRO 610HT, which has turn into the true workhorse of Diebold Nixdord. As demand for 3D printing has confirmed excessive on the firm, the machines are operating 24/7 all whereas making certain precision, one thing for which the FUNMAT PRO 610HT large-format 3D printer is well-known.

Moreover, with the FUNMAT PRO 610HT it was doable to make sure a superior floor end for complicated geometries. Thus serving to Diebold to realize extra refined finishes that resemble injected elements to fulfill venture specs. Excessive constancy was additionally key with tolerance all the way down to tenths of a millimeter, making certain that elements not solely match completely, but additionally functioned as anticipated.

Because of this, supplies had been additionally essential. FUNMAT PRO 610HT stood out for its potential to work with a variety of supplies, for the printing quantity that matches completely into their tasks and for not working with closed materials cartridges, as it really works with any model of filament.

Pinheiro expands, “ABS is our materials of alternative more often than not for its power and ease of use. Nonetheless, we’re at all times evaluating different supplies that may meet the wants of every venture. That is the benefit of the FUNMAT PRO 610HT, it’s a machine that accepts a variety of supplies.”

Final however not least, with the FUNMAT PRO 610HT, Diebold was capable of work with a variety of sizes. For instance, some tasks required small elements, however there was additionally demand for big parts. One such instance is the entrance panel a part of an ATM that was capable of benefit from virtually all the accessible printing quantity of the FUNMAT PRO 610HT (610 x 508 x 508mm).

The FUNMAT PRO 610HT (picture credit: INTAMSYS)

In any case, the usage of FFF 3D printing has been an enormous success at Diebold Nixdorf. The corporate additional notes that the manufacturing functionality they’ve achieved with AM adoption has allowed them to remain aggressive whereas assembly tight deadlines. Particularly contemplating the reliability of steady printing with the FUNMAT PRO 610HT. You may be taught extra about INTAMSYS 3D printing options HERE.

What do you consider Diebold Nixdorf’s choice to show to 3D printing for his or her automated banking options? Tell us in a remark beneath or on our LinkedIn, Fb, and Twitter pages! Don’t overlook to enroll in our free weekly e-newsletter right here for the most recent 3D printing information straight to your inbox! You too can discover all our movies on our YouTube channel.

*Cowl Picture Credit: INTAMSYS