3D printing has seen a number of success on Kickstarter, with notable examples together with the likes of Formlabs and Bambu Lab. These tasks have demonstrated the platform’s potential to fund improvements, propel them ahead and convey them to fruition. Now, Flovv and Flovv-e, new tasks combining desktop injection molding and 3D printing, are following in these footsteps, having already raised over $165,181 from an preliminary goal of $10,000, and with 28 marketing campaign days remaining.

Neckog Industries, the corporate behind this undertaking, is working to mix the strengths of 3D printing and response injection molding (RIM). Flovv and Flovv-e are the primary merchandise to be marketed by the American producer. They promise to push again the boundaries of each additive manufacturing and injection molding by producing sturdy, exact and versatile elements at better velocity and cost-efficiency.

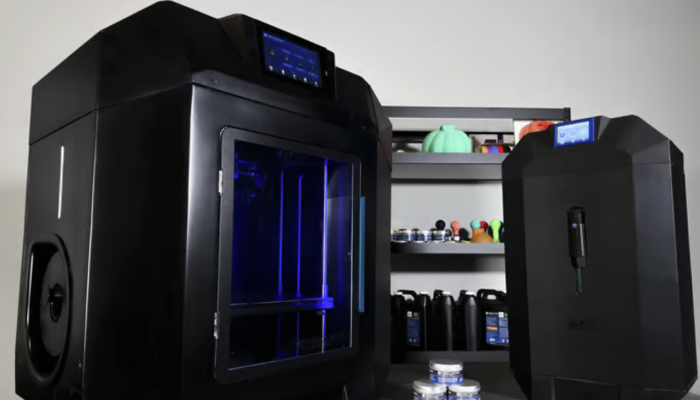

The Flovv-e printer and the Flovv machine each allow response injection for use with 3D printing

Combining 3D Printing and Response Injection Molding (RIM)

Flovv and Flovv-e goal to mix the complementary benefits of 3D printing and injection molding. 3D printing presents unrivalled design flexibility, however is ill-suited to mass manufacturing. Injection molding, then again, excels within the speedy manufacturing of high-quality elements, however its excessive value and lack of design flexibility make it inaccessible to many customers.

Flovv and Flovv-e bridge this hole by combining the benefits of each applied sciences. Utilizing RIM, they inject liquid polyurethanes into 3D-printed molds, creating dense, sturdy elements in only a few minutes. This strategy makes it doable to provide hihgly-precise, advanced elements with a excessive floor high quality end.

Polyurethane elements are created in 3D-printed molds

Flovv and Flovv-e Enable Customers to Uncover and Experiment With Injection Molding

The Flovv-e integrates a 3D printer and a response injection molding (RIM) machine right into a single module, whereas the Flovv serves as a stand-alone RIM unit. Relatively than plastic pellets, each gadgets exploit response injection molding, with the machines mixing two liquid supplies (polyurethane and a hardener) earlier than injecting them right into a mildew.

The Flovv-e includes a print quantity of 320 x 320 x 400 mm, a completely enclosed design, a heated chamber and a claimed most velocity of 300 mm/s. With this machine, it needs to be doable to print molds with ABS filament, apply a launch agent, then inject the mildew with numerous supplies (inflexible, versatile, foam).

The Flovv-e 3D printer options an built-in Response Injection Module (RIM)

The Flovv, then again, is an injection-only machine, designed for many who already personal a 3D printer. Each machines routinely combine polyurethane and hardener, avoiding the challenges of speedy resolution curing, and run a self-cleaning program after use.

Challenges Forward and Promising Purposes

The potential functions for Flovv and Flovv-e are huge and promising. The Kickstarter undertaking, which has already raised over $150,000 the preliminary objective, bears witness to the sturdy curiosity on this expertise. It’s necessary to keep in mind, nonetheless, that this can be a undertaking beneath growth, and its guarantees have but to be independently validated.

Neckog Industries’ injection options are suitable with quite a lot of polyurethane resins

Given the engaging value of the machines (introduced at $900 for the Flovv and $4,000 for the Flovv-e after the crowdfunding marketing campaign), Neckog Industries is conscious that a few of its public lack the expertise wanted to design advanced injection molds. That’s why the producer additionally presents a mildew design service (DaaS) to make its merchandise simpler to make use of. With DaaS, Neckog Industries takes cost of mildew design, enabling customers to focus on innovation and the creation of their finish merchandise. This service goals to simplify the manufacturing expertise and make it accessible to a wider viewers.

We are going to preserve an eye fixed out on the progress of this undertaking to evaluate its actual affect on the 3D printing business. Within the meantime, if you want extra data, be happy to go to the Neckog Industries web site HERE.

What do you consider the Flovv and Flovv-e? Tell us in a remark under or on our LinkedIn, Fb, and Twitter pages! Don’t neglect to enroll in our free weekly publication right here for the newest 3D printing information straight to your inbox! You can too discover all our movies on our YouTube channel.

*All Photograph Credit: Neckog Industries