Israel-based 3D printer producer Massivit 3D launched the Massivit 3000, its new large-format 3D printer, to the 3D printing market at TCT 3Sixty 2024.

In accordance with Avi Cohen, the corporate’s VP for Gross sales and Advertising and marketing, this new system is an inexpensive, high-speed addition to the large-scale 3D Printer market. In an interview on the Massivit sales space, Cohen acknowledged that the Massivit 3000 can 3D print massive elements “30 occasions sooner than every other system in the marketplace.”

He additionally shared insights on the full addressable marketplace for the large-format sector, and the way the Massivit 3000 is poised to use rising demand for know-how that may 3D print large elements quick.

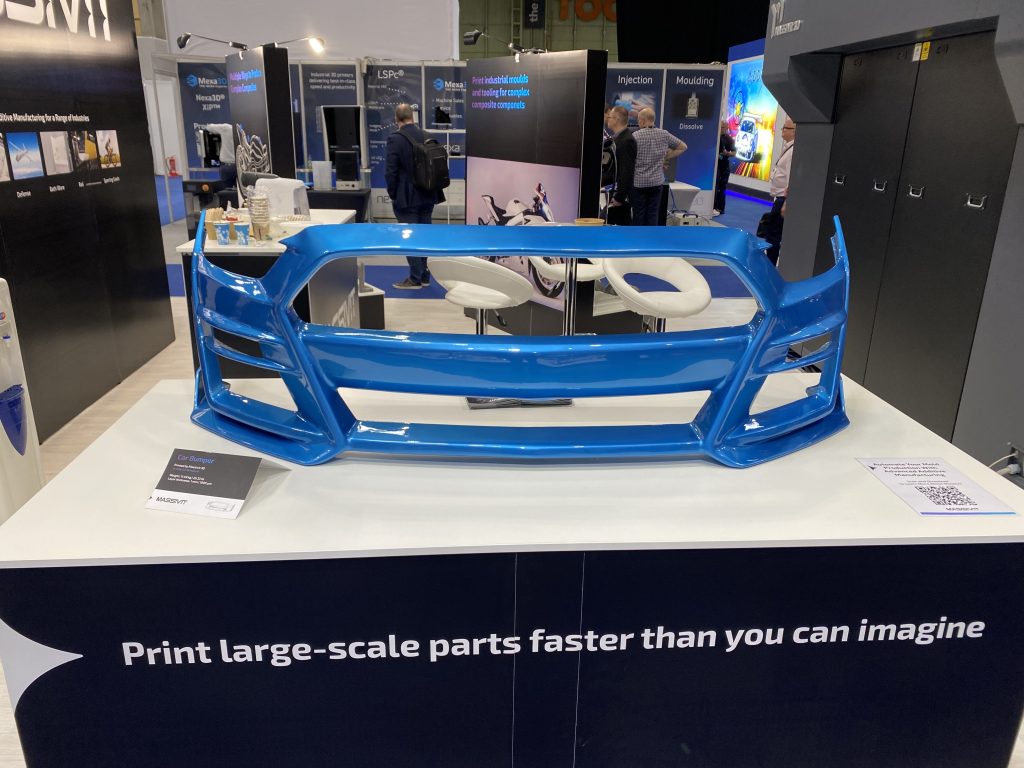

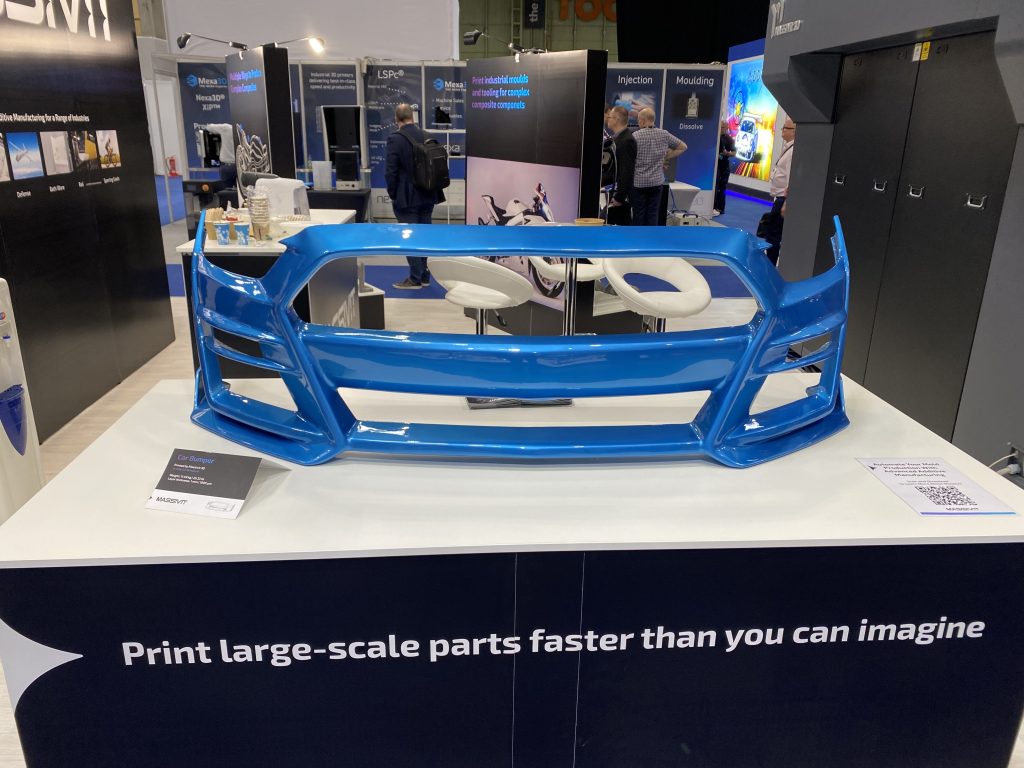

Incorporating Massivit’s distinctive Gel Shelling out Know-how, the brand new 3D printer is optimized for the marine, automotive, furnishings, visible communications and themed leisure sectors.

With costs beginning at €199,000, Massivit has already acquired curiosity for its latest product. Cohen revealed that the corporate not too long ago offered one of many 3D printers to a buyer within the industrial sector.

TCT 3Sixty was the primary additive manufacturing commerce present to characteristic the brand new Massivit 3000, marking its introduction to the 3D printing business.

The Massivit 3000: inexpensive and quick large-format 3D printing

Boasting a considerable 3D print quantity of ~1.2 x 1.5 x 1.8 m, the Massivit 3000 is right for customers eager to fabricate massive elements in a single 3D print job.

3D printing pace is a key promoting level of Massivit’s new providing, facilitated by the corporate’s proprietary Gel Shelling out Know-how. On this course of, photopolymer gels are extruded at excessive speeds earlier than being quickly cured into stable layers below UV mild.

This permits “very quick” 3D printing, based on Cohen. A 1.8-meter tall ice-cream cone mannequin was 3D printed in round 5 hours at TCT 3Sixty, “30 occasions sooner than every other know-how.”

A broad vary of polymer and acrylic supplies will be fabricated via the Gel Shelling out strategy, together with these with excessive energy and translucent traits. These supplies’ distinctive rheology and 0.8 mm layer thickness facilitate high-fidelity 3D printing and complex floor particulars.

As such, the Massivit 3000 is adaptable to numerous end-use purposes, starting from hole mild options to customized automotive bumpers and purposeful boat buildings. A fiberglass coating will be added post-3D printing to extend the energy and sturdiness of those large-scale, end-use elements.

The corporate’s distinctive extrusion course of additionally allows the Massivit 3000 to provide advanced geometries with out assist buildings. “We print hole,” defined Cohen, who emphasised that this strategy considerably reduces the fabric necessities for big elements, enabling value and weight financial savings.

Certainly, the Massivit 3000 was designed with affordability in thoughts. Cohen emphasised its “budget-friendly” worth level, which is able to permit many extra individuals to use the advantages of Massivit’s know-how.

He believes this aggressive pricing differentiates the brand new system in a rising sector. In accordance with Cohen, the full addressable marketplace for large-scale additive manufacturing is “big,” encompassing a whole bunch of machines every year and an rising variety of new purposes.

Cohen is assured in Massivit’s skill to use this increasing market, proclaiming that the corporate is effectively positioned to “conquer the world” of large-format 3D printing.

Technical specs of the Massivit 3000

| 3D Printing Know-how | Gel Shelling out Know-how |

| 3D Print Heads | 1 3D Printing Head |

| Materials Techniques | 1 Materials System |

| 3D Print Quantity | W x L x H: 145 x 111 x 180 cm / 57” x 44” x 70” |

| 3D Printing Decision | 0.8 mm / 1.0 mm / 1.3 mm |

| Movement System | Servo Motors |

| 3D Printing Materials | Dim 90, Dim 100, Dim 300 |

| Workflow and Software program | Massivit Good SlicerSoftware on machine: Massivit proprietary front-end software program. Enter format: STL |

| System Dimensions | W x L x H: 3 x 2.2 x 2.8 m / 119” x 97” x 110” |

Need to assist choose the winners of the 2024 3D Printing Business Awards? Be a part of the Knowledgeable Committee at this time.

What does the way forward for 3D printing maintain?

What near-term 3D printing tendencies have been highlighted by business specialists?

Subscribe to the 3D Printing Business e-newsletter to maintain updated with the most recent 3D printing information.

You can even comply with us on Twitter, like our Fb web page, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Featured picture exhibits Avi Cohen, VP Gross sales and Advertising and marketing at Massivit, and the brand new Massivit 3000. Picture by 3D Printing Business.