Massivit 3D Printing Applied sciences has reported a profitable launch week for its new Massivit 3000 additive manufacturing system, which was launched final week at drupa in Germany and at TCT 3Sixty within the UK.

The big-format 3D printing firm has signed 15 new buy orders, valued at 3 million USD, with deliveries slated to be accomplished earlier than the top of the yr. It has additionally acquired a further two buy orders from Bombardier for its Massivit 1800 system, and from Navistar, an American truck and bus firm owned by Volkswagen, for its bigger Massivit 5000.

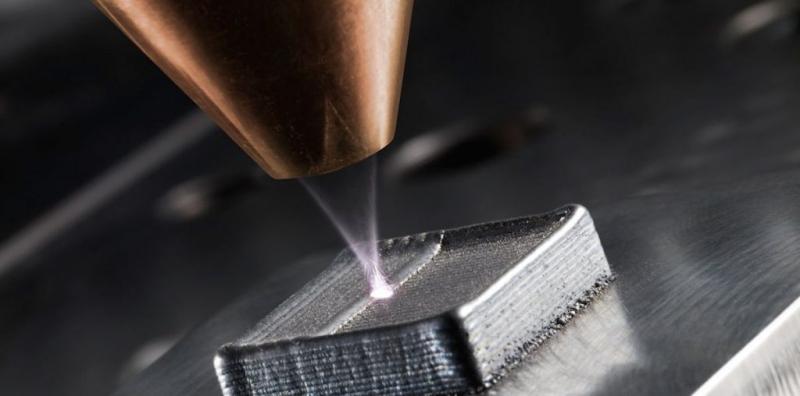

The Massivit 3000 is alleged to be a extra reasonably priced, high-performance 3D printing answer tailor-made for the manufacturing of huge finish elements and prototypes. The Massivit 3000 affords a print quantity of 1.2 x 1.5 x 1.8 metres and harnesses the ‘extremely high-speed manufacturing’ capabilities of Massivit’s superior Gel Meting out Printing expertise. With these options, Massivit believes producers will be capable of swiftly produce full-scale elements for the marine, automotive, rail, visible communications, and theming industries.

Erez Zimmerman, CEO commented: “The Massivit 3000 permits corporations within the promoting and advertising and marketing industries to print large-scale objects ultra-fast. These printed gadgets can be utilized as point-of-purchase shows, window shows, and billboards.”

In the identical week, the corporate additionally took dwelling two TCT Awards. The primary was for its CIM 84 materials, the primary licensed flame retardant 3D printing materials which permits corporations within the theme park business to supply flame-rated inventive development. Disney Imagineering acquired the Massivit 10000 final yr to fabricate elements for its theme parks. The corporate was additionally awarded the TCT Shopper Product Utility Award - Sponsored by Lastly Company for the Superyacht Sundeck Scorching Tub, which noticed Massivit staff up with Woltz Nautic to supply 3D printed scorching tub in its proprietary Dimengel thermoset acrylic. The recent tub weighs 100 kg lower than conventional counterparts and considerably reduces set up time by roughly 260 hours per tub.