Nominations for the 2024 3D Printing Trade Awards at the moment are open. Inform us who’s main.

Following its strategic reorganization, German multi-material 3D printing firm AIM3D has revealed the advantages of its patented Voxelfill course of, which addresses inconsistent energy in 3D printed elements.

This novel expertise enhances mechanical properties in all instructions together with X, Y, and Z thereby bringing 3D printed elements nearer to the energy achieved by way of conventional manufacturing strategies, similar to injection molding. Having validated this course of by way of in depth testing, AIM3D with its Voxelfill course of has considerably improved the tensile energy and general half sturdiness of the corporate.

Clemens Lieberwirth, CTO at AIM3D, “After all, the Voxelfill course of is especially appropriate for 3D printing plastics and fiber-filled plastics, however it’s also appropriate for the 3D printing of metallic and ceramic elements utilizing the CEM course of. Basically, the principle benefits are a better construct pace and cross-layer filling.”

Voxelfill enhances tensile energy and presents cost-efficiency

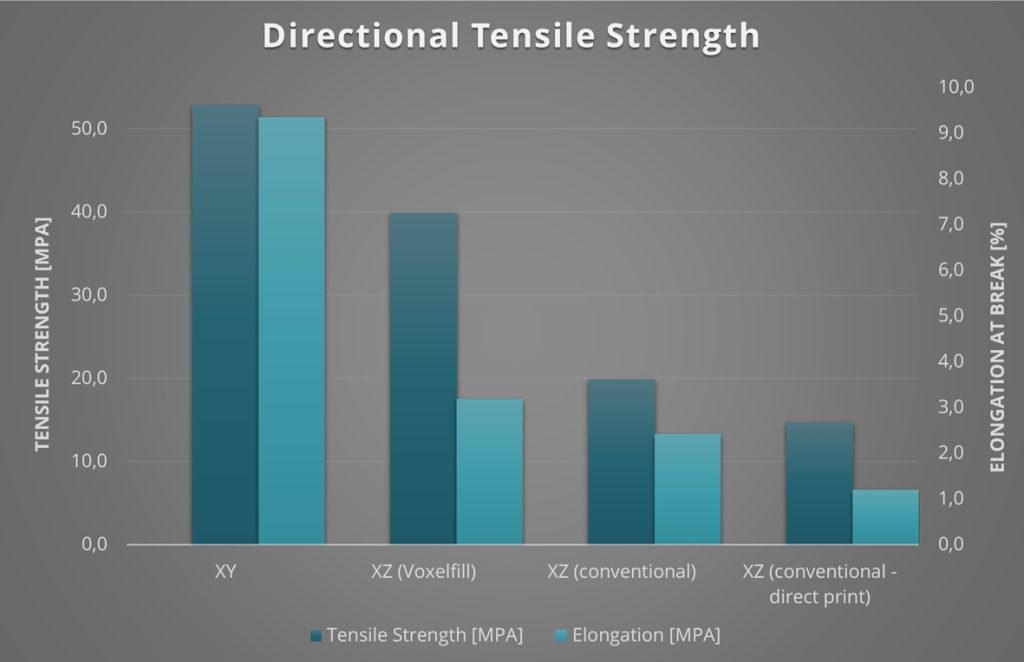

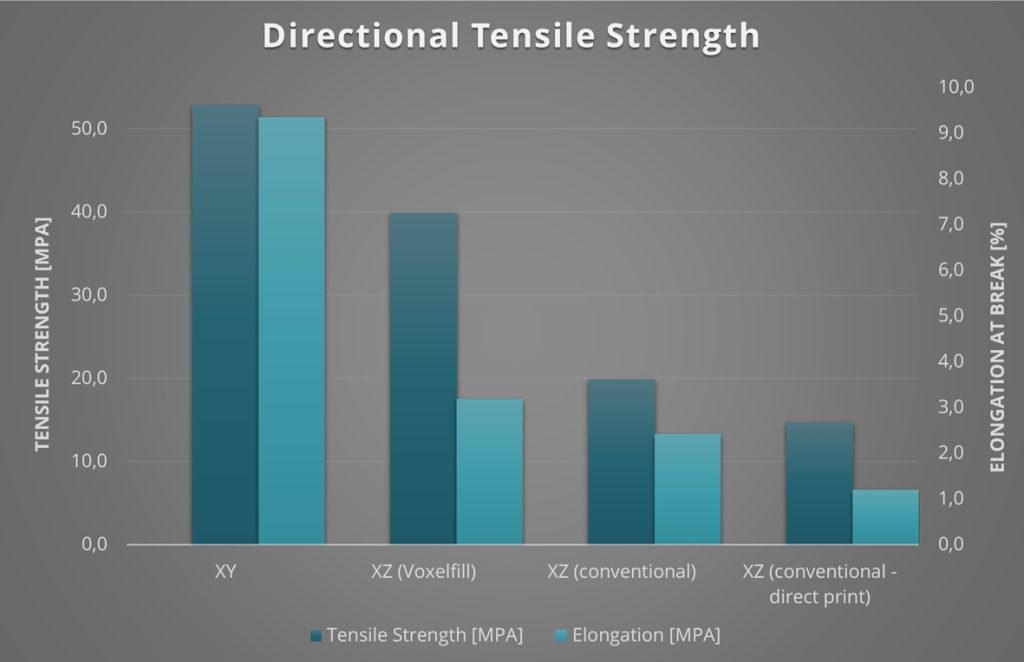

The Voxelfill course of enhances 3D printed elements’ tensile energy, attaining as much as 80% of injection-molded energy, with a possible for 100%. It addresses the Z-axis weak point in conventional 3D printing by combining extrusion printing with injection molding to scale back anisotropy and enhance structural integrity.

This course of was examined throughout totally different orientations, together with variants A, B, and C, which assessed tensile energy in each horizontal (XY) and vertical (Z) planes. Horizontal elements achieved strengths of 53 MPa, whereas vertical specimens, typically a weak level in 3D printing, noticed energy enhancements from 20 MPa (conventionally printed) to 40 MPa with Voxelfill. Additional optimizations are ongoing, specializing in enhancing filling density to reduce air inclusions and improve tensile energy.

Based on AIM3D, its pellet 3D printers additionally supply cost-effective manufacturing. By utilizing reclaimed supplies and lowering materials prices, these printers present a extra economical answer in comparison with conventional FDM printers. Lieberwirth emphasised that the corporate’s Composite Extrusion Modeling (CEM) expertise reduces prices and allows the creation of elements with mechanical properties which might be just like these of injection-molded elements.

Materials versatility and broad industrial purposes

Voxelfill is suitable with a variety of supplies, together with fiber-filled polymers like PA6 GF30 and PETG, in addition to high-performance thermoplastics similar to ULTEM 9085. This versatility makes it appropriate for industries like automotive, aerospace, rail automobiles, and protection, the place sturdy, heat-resistant supplies are important. Particularly, Sabic ULTEM 9085 presents flame retardancy and may stand up to excessive temperatures, making it superb for demanding purposes.

Supporting multi-material printing, the Voxelfill course of permits producers to customise totally different properties similar to weight, energy, and suppleness throughout numerous elements of a element. This characteristic is especially helpful for creating light-weight but sturdy elements and is suitable with plastic, metallic, and ceramic supplies, additional broadening its industrial purposes.

In current exams with fiber-filled supplies, similar to PETG GF30, the advantages of Voxelfill have been clear, says the corporate. Horizontal specimens reached tensile strengths of 72.4 MPa, whereas vertical specimens achieved 40.7 MPa, far surpassing the outcomes sometimes obtained by way of standard 3D printing strategies. The expertise improved the homogeneity of energy, reaching 81% in comparison with simply 25% in normal 3D printed elements.

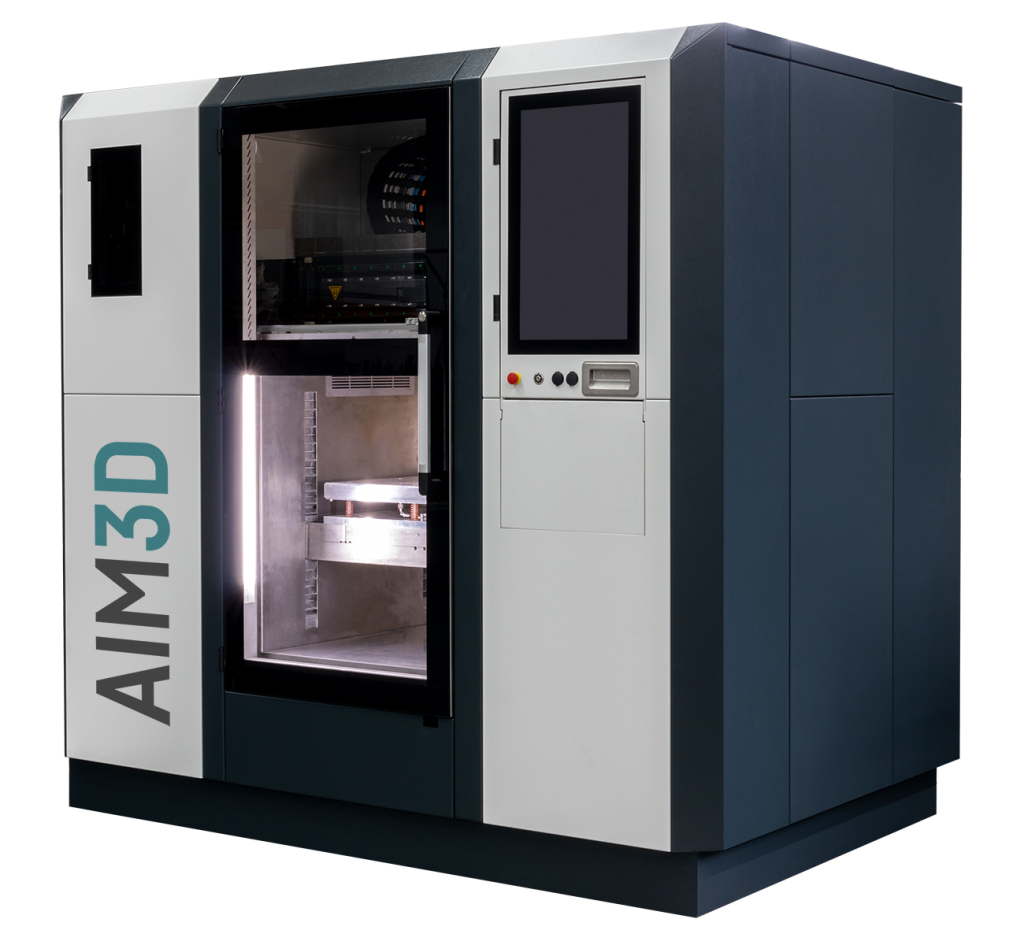

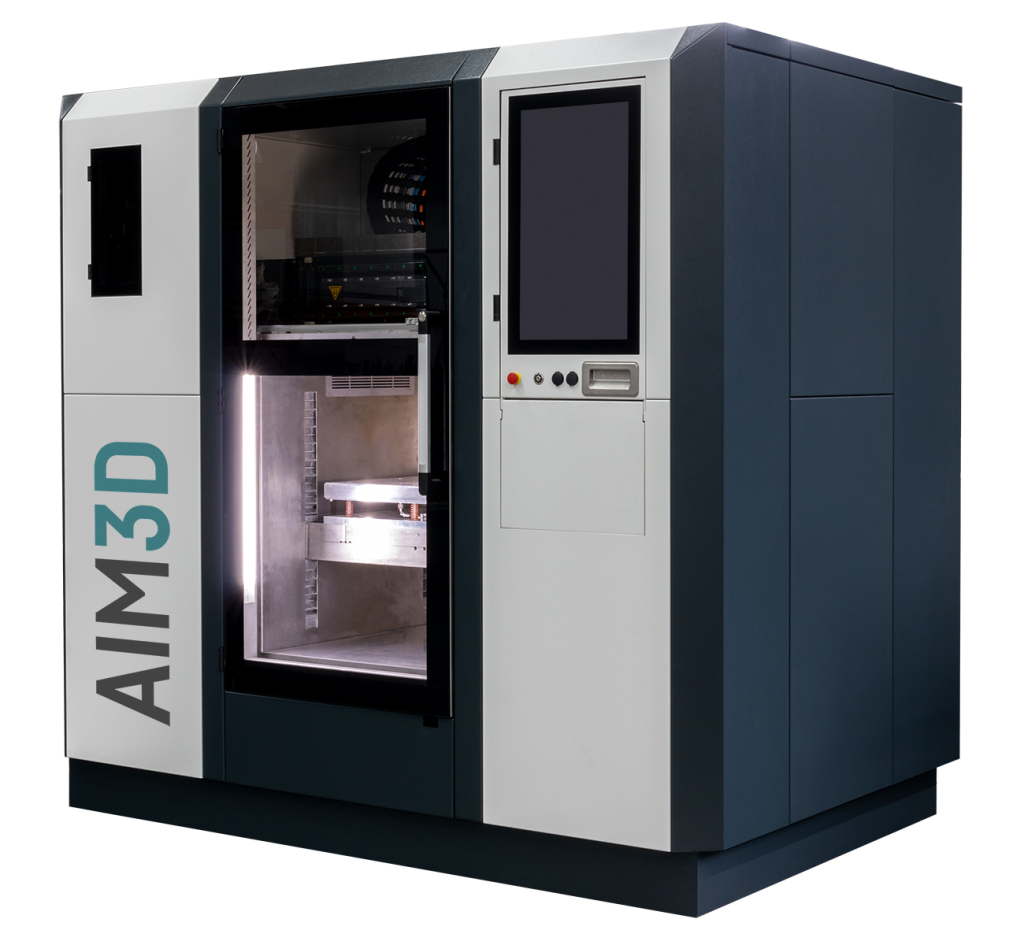

Moreover, AIM3D’s ExAM 510 system, outfitted with Voxelfill, at the moment helps construct charges of 150 cm³/h, with future upgrades deliberate to extend capability to 300–600 cm³/h. This method additionally helps PEI (polyetherimide), a flame-retardant materials recognized for its sturdiness in high-temperature environments. Using Sabic ULTEM 9085 with this technique allows the manufacturing of elements with properties intently matching these of injection-molded elements.

The corporate plans to proceed refining the Voxelfill course of, specializing in materials versatility and efficiency optimization. With the potential to additional enhance tensile energy and develop its utility throughout numerous industrial sectors, AIM3D’s Voxelfill expertise is anticipated to play a key function in the way forward for 3D printing.

Up to now, the Voxelfill course of discovered utility with the Danish software program agency Create it REAL. The corporate partnered with AIM3D to combine the Voxelfill course of as a plug-in for the ExAM 255 and ExAM 510 techniques through its SlicEx software program. Throughout Formnext 2023, each showcased the software program and plug-in, enabling selective densities in 3D printed elements comprised of metals, plastics, and ceramics.

What 3D printing tendencies do the trade leaders anticipate this yr?

What does the Way forward for 3D printing maintain for the subsequent 10 years?

To remain updated with the newest 3D printing information, don’t neglect to subscribe to the 3D Printing Trade e-newsletter or comply with us on Twitter, or like our web page on Fb.

Whilst you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Featured picture reveals the AIM3D staff. Picture through AIM3D.