Thermoforming corporations and producers that make the most of thermoformed elements are at present underneath immense aggressive stress to enhance manufacturing effectivity, decrease waste, and decrease bills. Concurrently, they’re grappling with a shortage of expert labor. Fortuitously, additive manufacturing (AM) presents a compelling resolution. With AM, corporations can entry high-performance molds that not solely type top-notch elements but in addition considerably lower down on lead instances and labor bills when in comparison with typical mold-making approaches. On this webinar, titled “Revolutionizing Thermoforming: Unleashing Effectivity to Drastically Scale back Mould Manufacturing Time & Prices“, you’ll learn to obtain speedy validation by testing shapes and delivering first elements as much as 65% quicker with 3D printed molds.

Watch Now!

Specialists from 3D Programs will present how the corporate’s thermoforming prospects declare to have run 1000’s of photographs of 3D printed molds with just about no indicators of wear and tear or efficiency degradation. Register now and uncover how different corporations used our pellet extrusion expertise to lower price and shorten lead instances for giant thermoforming molds!

Subtractive versus additive manufacturing molds

Additive manufacturing provides quite a few benefits over subtractive manufacturing, significantly when it comes to design flexibility, manufacturing pace, and value effectivity. It permits for the optimization of geometric options tailor-made to particular utility wants with out the compromises required by conventional processes. Turnaround instances are considerably quicker, as 3D printing can produce molds inside hours or days in comparison with the weeks or months wanted for conventional mold-making. This technique additionally minimizes waste and reduces uncooked materials prices by producing close to web shapes, enabling producers to machine printed elements relatively than giant blocks of fabric.

Register right here to observe the webinar now.

Moreover, the prices of supplies and elements are a lot decrease in comparison with conventional ceramic, steel, and wooden molds. Polymers, particularly, supply an extended shelf life and higher resistance to environmental elements like moisture and temperature than wooden. Additive manufacturing additionally permits for the creation of porous molds that optimize molten plastic stream by eliminating the necessity for drilled vacuum channels. Moreover, sustaining a digital stock of molds eliminates the necessity for bodily storage, as customers can recycle printed molds and retain their digital recordsdata, making mould alternative fast and straightforward by reprinting.

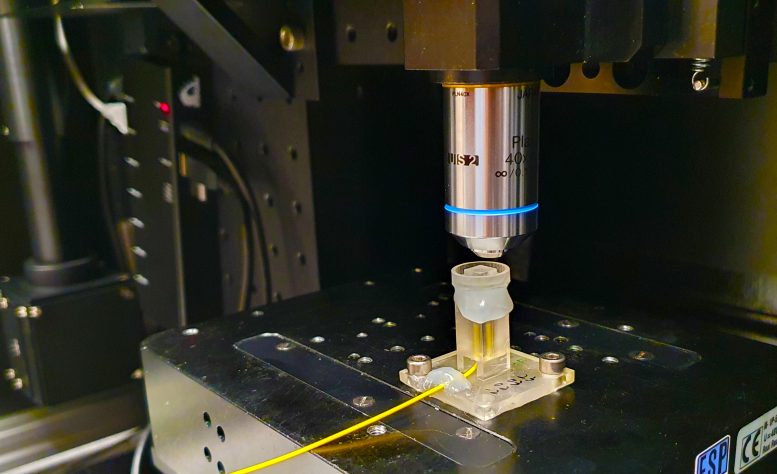

In typical thermoforming, plastic sheet materials is formed over patterned molds to create the completed half, usually utilizing vacuum forming to assist pull the plastic sheet over the mould. These molds could be produced by varied strategies, equivalent to CNC machining of metals and ceramics and even hand-sculpting wooden. These subtractive processes usually contain CNC milling and tooling, the place materials is selectively faraway from a block utilizing a spindle to attain the specified form. In distinction, additive manufacturing begins with nothing and builds a component, layer by layer on a construct platform, utilizing solely the mandatory materials. This method permits for the creation of elements from a variety of polymers, together with customary and high-performance thermoplastics, thermoset, stuffed and photopolymer resins, and even metals. Additive manufacturing programs are available in varied sizes, from small desktop items to large-format industrial machines, providing versatility in manufacturing capabilities.

Agenda of the webinar

- Introduction

- The Buyer Problem: Value, Lead Time & Stock

- The Additive Answer: Industrial, Giant-Format Platforms; Pellet Extrusion vs Filament Extrusion; Ideas & Finest Practices for Printing Molds

- Assorted Buyer Use Circumstances

- Conclusion and Q&A

Speaker

Haley Stump

Haley Stump is the Utility Engineer Lead for the Titan division of 3D Programs. She is on the forefront of many thrilling tasks involving the superior EXT Titan Pellet 3D printing system. In her earlier function, she labored with Titan as a buyer, growing time and value saving manufacturing strategies for a worldwide retail merchandising firm and joined the 3D Programs staff in Colorado Springs in 2022. She works carefully with our gross sales staff to offer tailor-made options for varied purposes equivalent to patterns, tooling, prototyping, and end-use merchandise.

What did you consider the webinar on-demand about thermoforming and 3D printing? Tell us in a remark beneath or on our LinkedIn, Fb, and Twitter pages! Don’t overlook to join our free weekly e-newsletter right here for the newest 3D printing information straight to your inbox! You may also discover all our movies on our YouTube channel.

*All picture credit: 3D Programs